A common Santos de Cartier movement consists of 138 individual parts. Omega’s technical-genius Speedmaster tallies just north of 200, while IWC’s mechanically poetic perpetual calendar movements house 385 parts. Still puny when compared to the world’s most complicated timepiece: Vacheron Constantin’s Berkley Grand Complication (debuted at W&W24), which brings 63 unique complications to life, employing a mind-boggling total of 2,877 parts. But, what are these ‘parts’ being referred to?

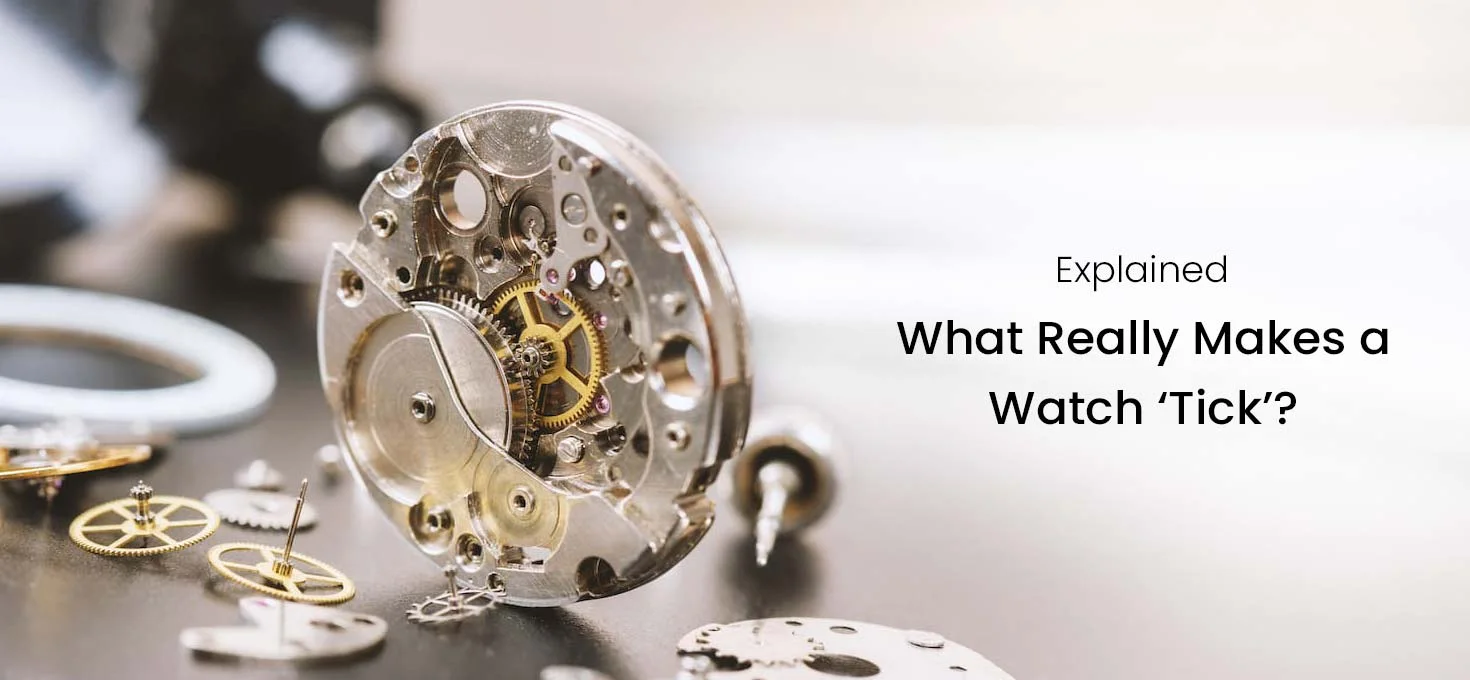

Watchmaking has endured nearly six centuries of evolution – pushing the envelope of accuracy, complexity, and miniaturization. But have we ever wondered what brings these little ticking gears and springs to life? To pop the case open and peek beneath the dial?

Here’s a simplified guide to understanding watch movements, their quintessential components, and what makes them ‘tick.’

Firstly, What’s a Watch Movement?

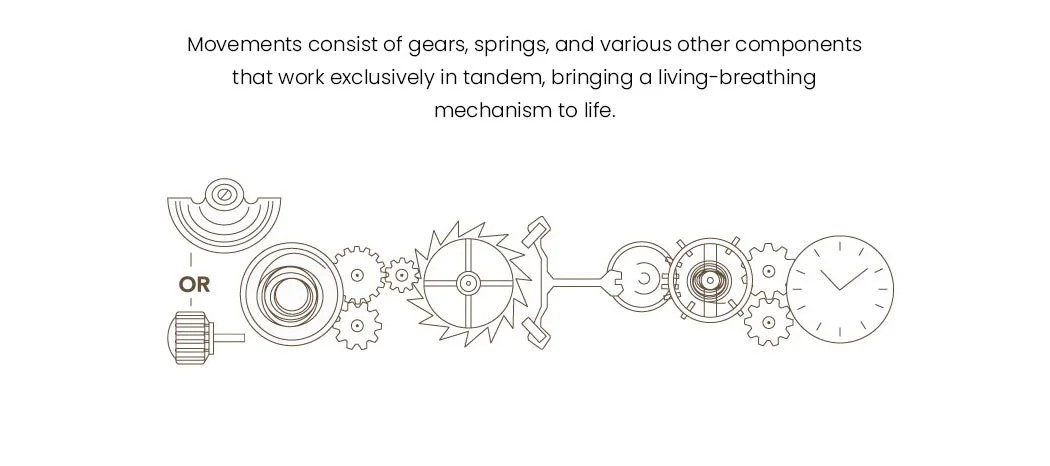

Engines to automobiles, propellers to planes, and motherboards to supercomputers – a movement is a timepiece’s beating mechanical heart and the lifeblood of its existence. Without it, your timepiece is merely a still dial bearing lifeless hands and displays. Movements consist of gears, springs, and various other components that work exclusively in tandem, bringing a living-breathing mechanism to life. It creates the function of indicating day, date, hour, minute, seconds, and so on.

The earliest concepts of mechanical self-winding movements can be traced back to 1777, developed by Abraham-Louis Perrelet for usage in pocket watches. While some watchmakers source their movements from specialized makers, others develop their own, these are called ‘manufacture’ movements or in-house movements.

Just like diesel, hybrid, and electric car options, your timepiece movement comes in various makes, too. These are primarily categorized as manual wound, automatic (self-winding), or quartz. But before we get into that, here’s a crash course on the various common components of a movement.

- Crown: Twistable knob, often grooved for grip which allows the wearer to wind the mainspring and set time. Located traditionally on the outer side of the case at 3 o’clock.

- Mainspring: Coiled metal strip housed within the mainspring barrel. Upon unwinding, it incrementally releases energy to the gear train – ensuring movement of the timepiece’s hands.

- Escapement: Consists of an escape wheel and pallet fork. This regulates the release of energy from the mainspring, delivering precise pulses to the balance wheel and maintaining the timepiece’s rhythm and accuracy.

- Balance Wheel: Swinging back and forth, the balance wheel governs the timing of the gear train’s movement. Its consistent oscillation ensures the flow of energy.

- Hairspring: Critical to the timepiece’s precision, the hairspring is a delicate coiled spring that’s attached to the balance wheel. This ensures the balance wheel remains in a consistent neutral position when oscillating.

- Dial Train: As the final link in the chain of motion, the dial train consists of gears situated between the gear train and hands. It facilitates the correct rotation of speed for the hour and minute hands. Careful assembly is critical to the timepiece’s accuracy.

- Jewels: Pivot points of gears and other moving parts cast out of synthetic rubies or sapphires. With low friction and durable properties, it enhances the movement’s longevity.

- Bridges and Plates: Ribcages of the movement that act as a structural framework. These hold the gears, escapement and other parts in place. Plates are typically large flat discs while bridges support the movement, providing stability and alignment.

- Rotor: Self-winding semicircular weight that pivots with wrist motion, winds the mainspring and maintains power without manual winding.

Manual Movements

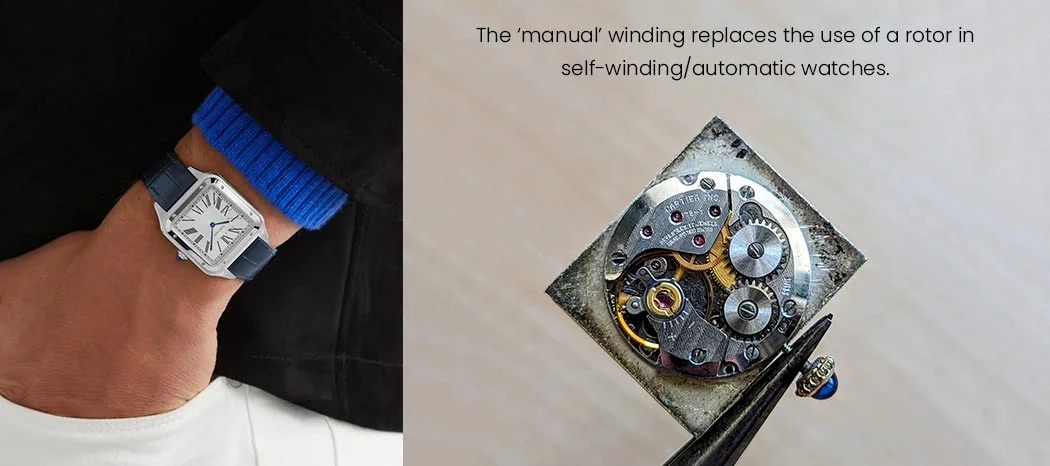

Manual-wound mechanical movements or hand-wound movements require you to physically twist the crown for it to be wound. Power reserves play critical roles in the experience of manual watches, as it’s determined by the intervals between each winding. This typically ranges between 35 to 70 hours.

The ‘manual’ winding replaces the use of a rotor in self-winding/automatic watches. As you twist the crown, the mainspring coils up and stores energy. This is transferred to the escapement thanks to the gear train. The escapement is responsible for distributing energy to different parts of the movements. The balance wheel uses this dispersed energy to swing back and forth in perpetual motion. With each swing, the dial train transfers the energy to the hands of the watch. Quick note of caution: Overwinding your timepiece can damage your movement – you can feel the tension build as you go over the edge.

Self-Winding Movements

Unlike manual movements, self-winding or automatic movements employ balance wheels and rotors. The rotor’s graceful 360-degree, pendulum-like swing, which can be viewed from the caseback, is an oscillating metal mass. This ergonomically and organically winds simply by the movement of the wrist. This rotor is a semi-circular metal part which can swing 360 degrees freely. As the rotor swings, it winds up the mainspring. Once this is fully wound, the gear train transfers energy to the escapement, which further distributes it to respective complication parts.

This movement activation is instantly apparent in the form of a true mechanical dance. Once in motion, the energy utilized by the balance wheel beats back and forth at a consistent rate, completing the transfer of energy all the way to the timepiece’s hands.

Quartz Movement

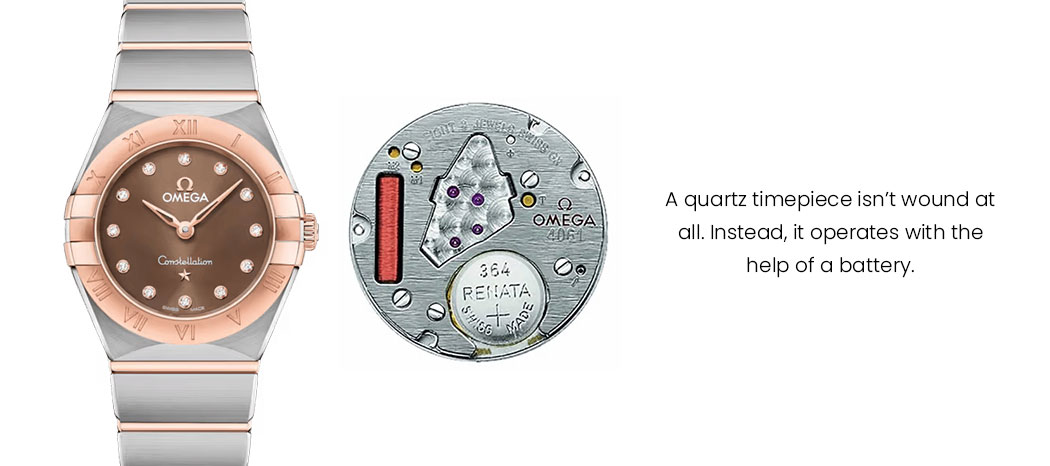

In 1969, the advent of the Quartz invention was one of watchmaking history’s most daunting times. Challenging the status quo with innovation, pushing marque watchmakers to the brink of bankruptcy. But what made the quartz timepiece such a pioneering icon?

To begin, a quartz timepiece isn’t wound at all. Instead, it operates with the help of a battery. The battery’s electric charge is carried to the quartz crystal through an intricate circuit, causing it to vibrate. This takes place at a precise rate of 32,768 Hz per second. As the electrical pulses reach the stepping motor, they power the dial train, advancing the timepiece’s hands.

While mechanical movements offered a 35 – 75-hour power reserve, quartz battery watches could last between one to two years and could be effortlessly and accessibly replaced. The battery does pose one risk to the movement: If it isn’t replaced in time after dying out, it could naturally degenerate and leak onto the movement’s metal parts. As of today, quartz movements are the most precise instruments in common markets.

Recent Posts

Recent Comments

Archives